Quality means everything to us. If our products are not quality, then we don’t care to share and sell them with you. There’s plenty of bad quality parts and accessories out there for whatever needs you have that come at a cost of longevity and reliability. If budget is your thing then you can settle for those – heck even we settle for cheaper and lower quality stuff time to time for things that are not die-hard important.

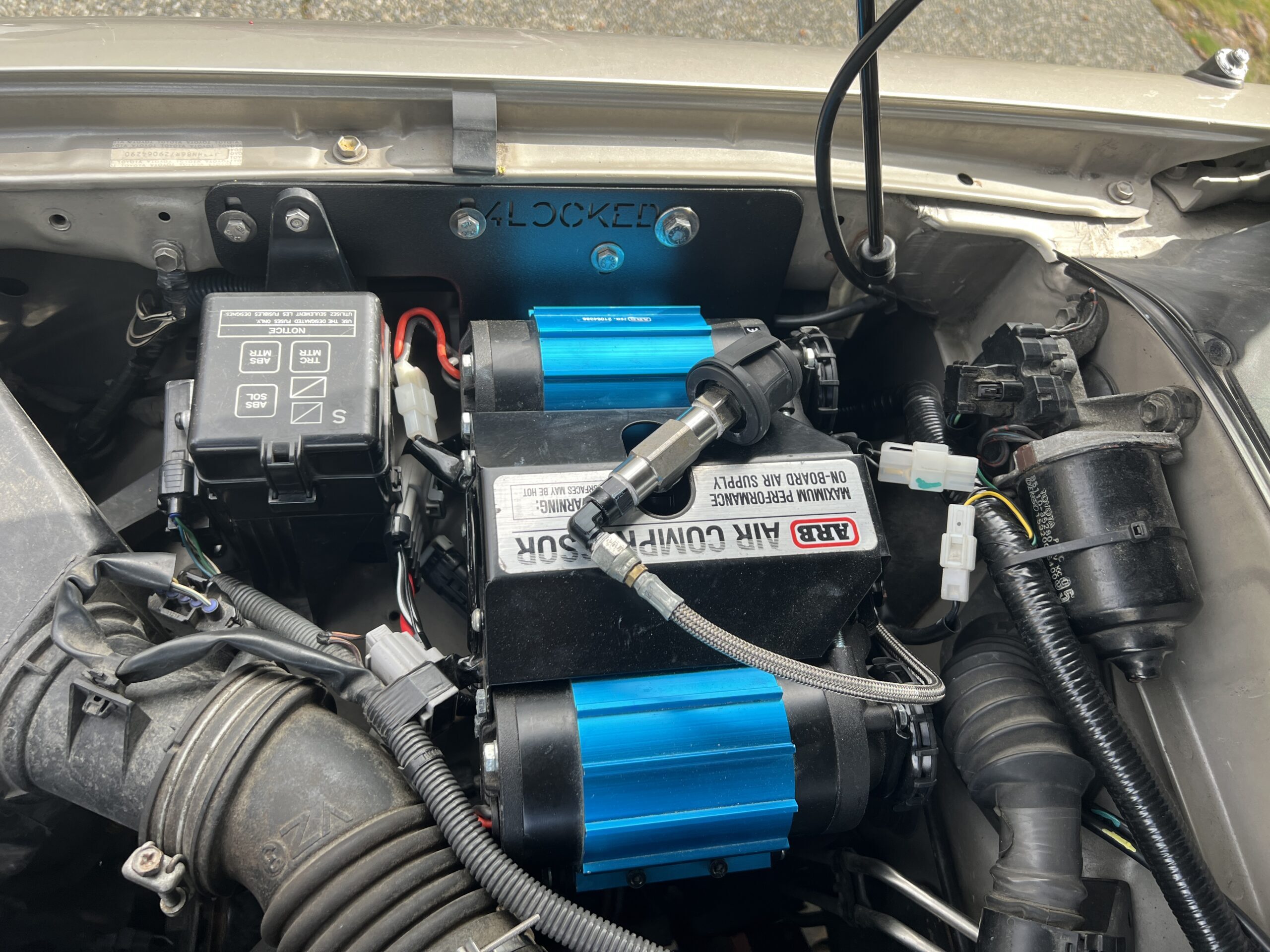

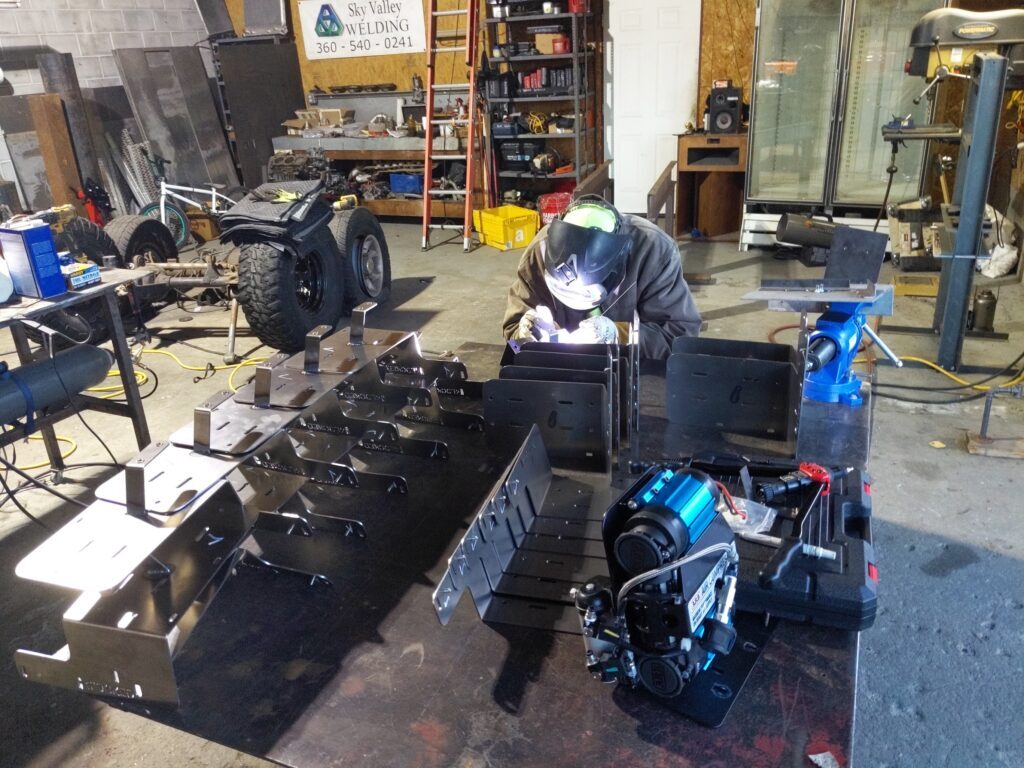

This very reason – quality – is why we opt to drive 6 hours round trip to drop off our ARB air compressor brackets for welding and another 6 hours round trip to pick them up. We use a talented welder, Warren House, based out of Warden, Washington. A tiny quaint and quiet town surrounded by farms just south of Moses Lake.

3rd Gen Toyota 4Runner/1st Gen Toyota Tacoma ARB Air Compressor Bracket Mount

$164.99

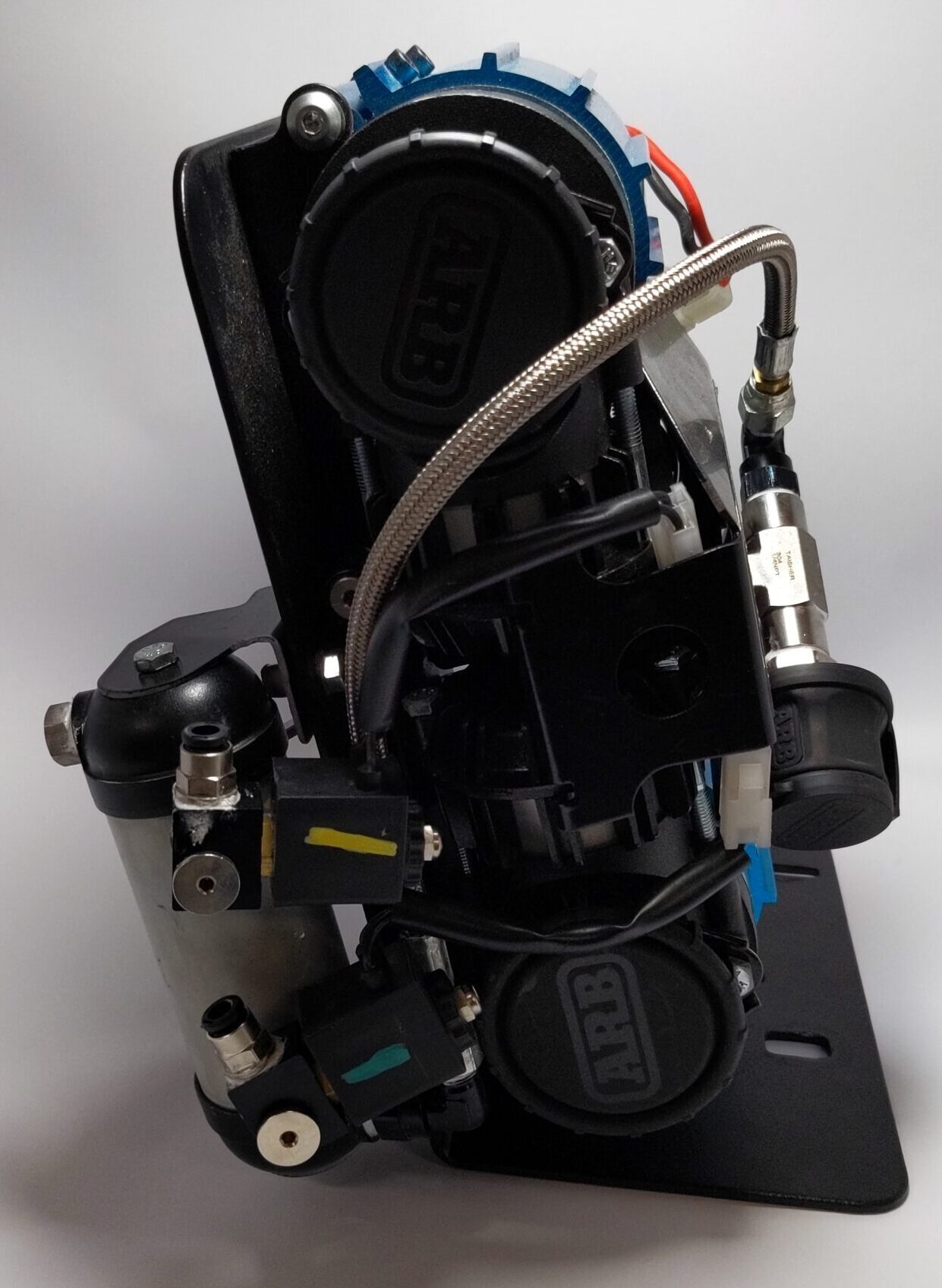

Stock is running low—once it's gone, it may be a while before it's available again!Our Air Compressor Bracket Mount for ARB and EGOI2 air compressors are designed specifically for 3rd Gen 4Runner and 1st Gen Tacoma. This heavy-duty bracket offers a straightforward installation with no drilling required, ensuring a perfect fit and reliable performance for your off-road adventures.

Description

- Easy install, installs in minutes for most.

- No Drilling Required

- Compatible with All Cruise Control Modules

- Fits Various Models

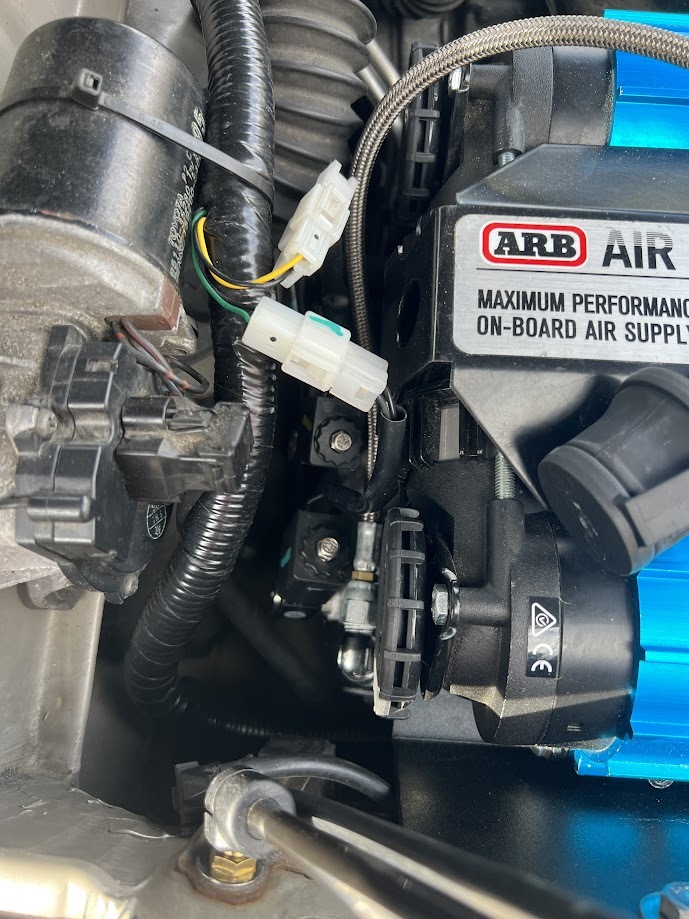

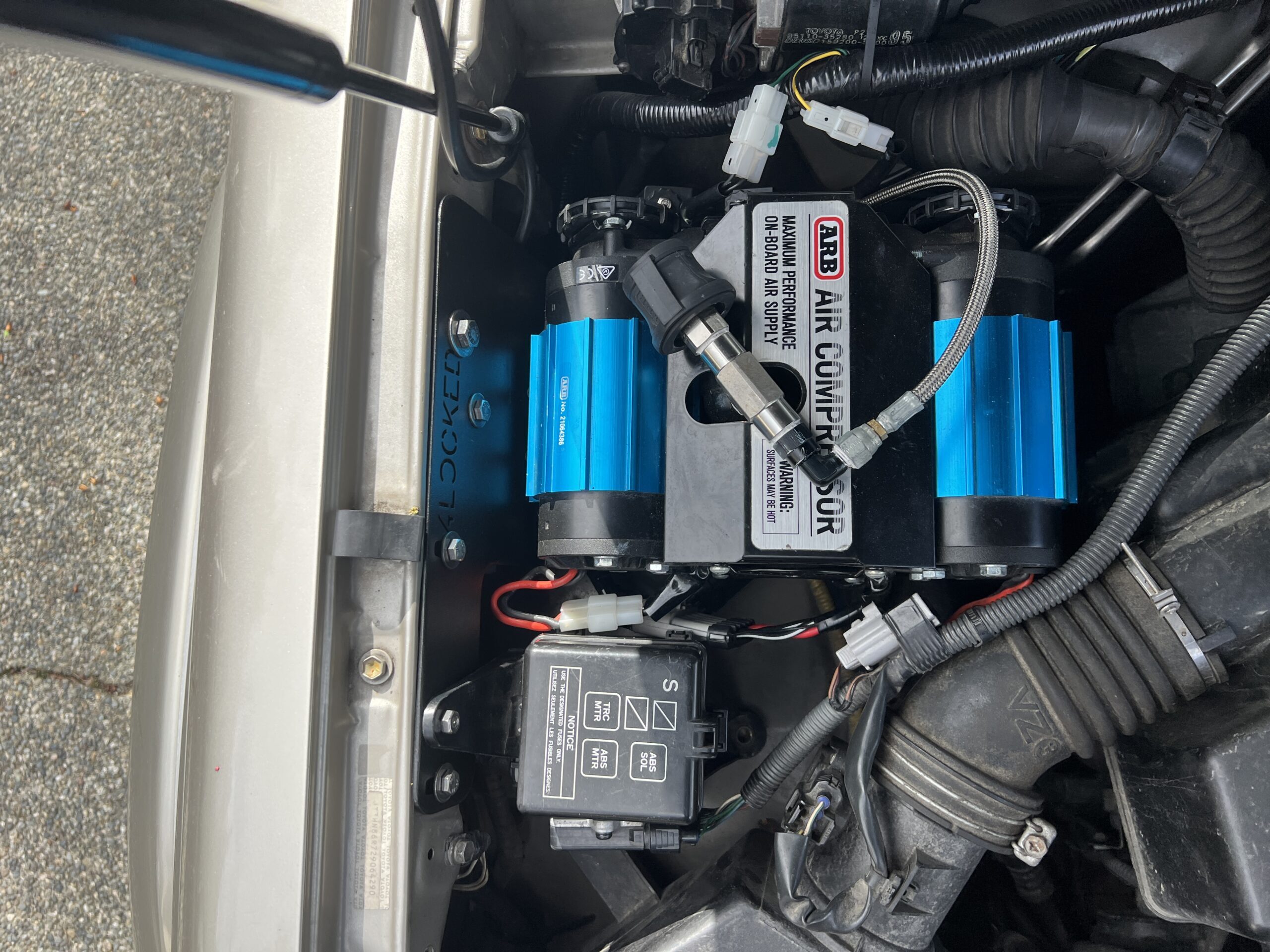

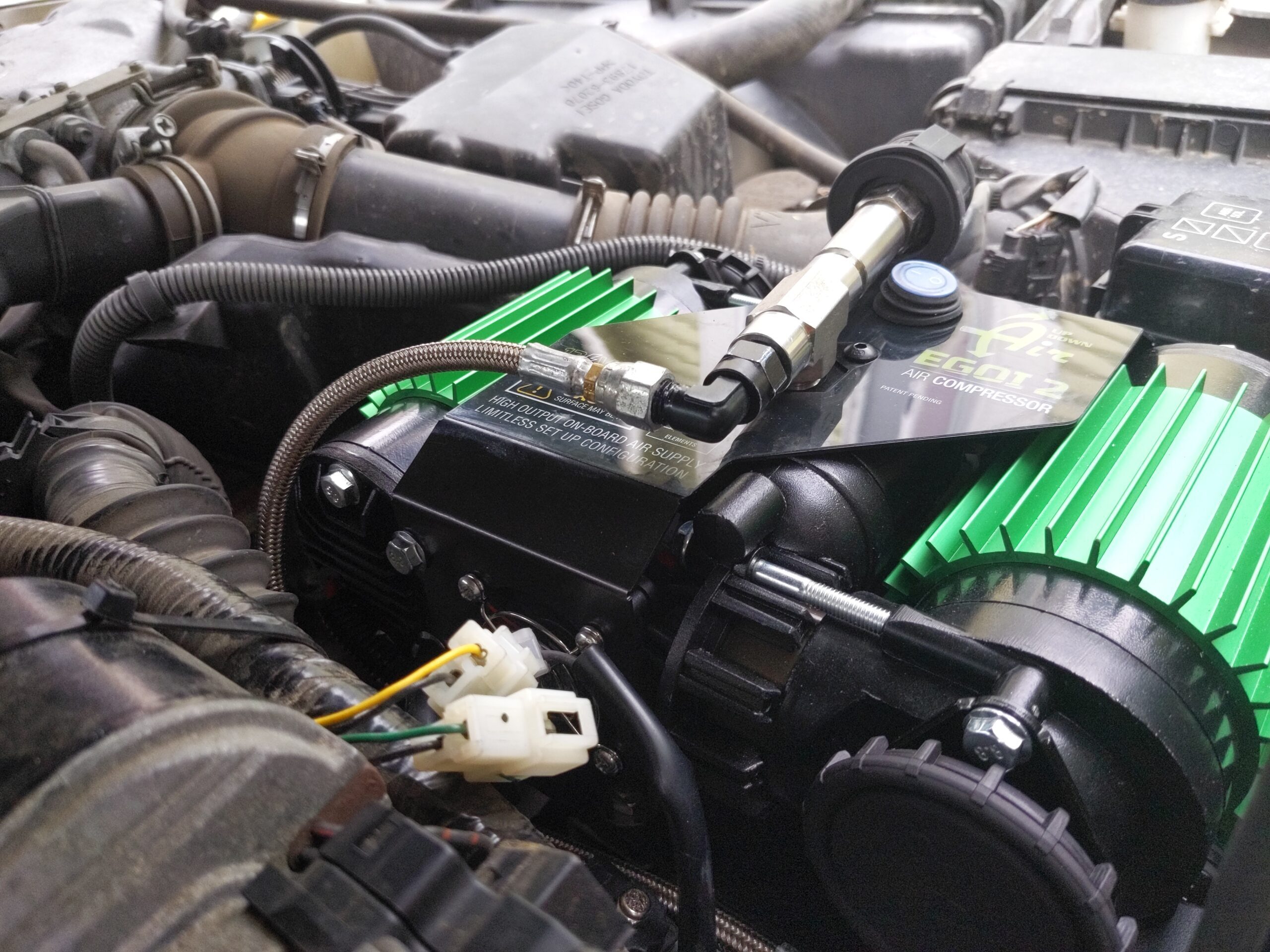

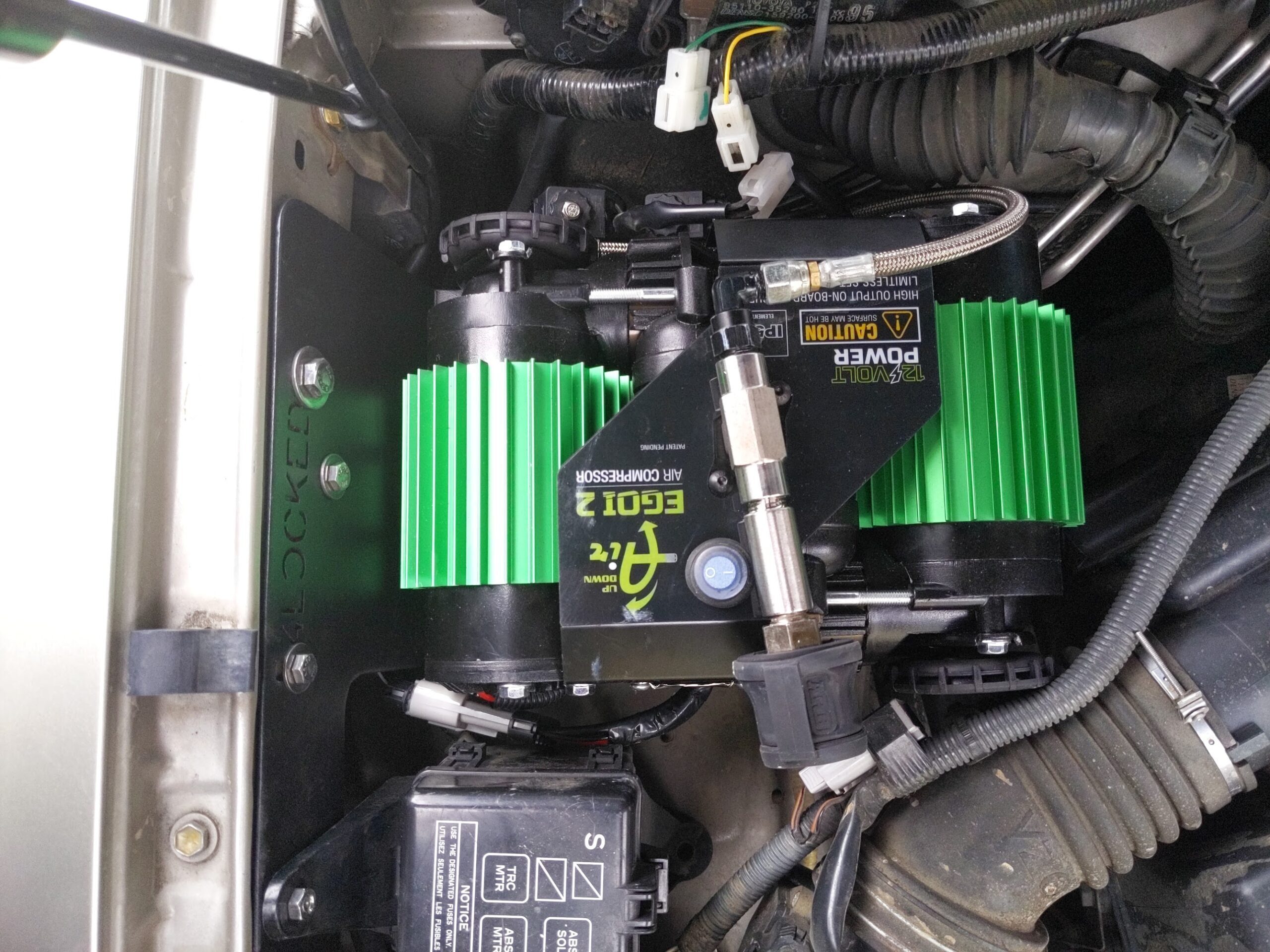

Mount your ARB Twin (ARB CKMTA12 / CKMTA24), ARB Single (ARB CKMA12 / CKMA24) or an EGOI2 air compressor. For those running air lockers this will also mount your ARB air locker manifold (ARB 171503) as well. These mount on the passenger side of the engine bay using factory holes. No drilling or tapping required.These are designed to withstand the harsh engine bay and each one is powder coated and come with a Lifetime Limited Warranty. Why put up with a noisy air compressor in the cab? Don’t give up your 4Runner’s cargo cubby storage to your air compressor and its systems – keep the cubby for yourself and move the air compressor and its components to the engine bay where they belong. Benefits of using this bracket (compared to in-cab installs):

- Closer to the car battery, reducing the need for long runs of wire.

- Noise is kept under the hood and behind the firewall.

- Leave your windows or doors closed when airing up tires or using air tools. On a cold winter night or hot summer day your family will appreciate your quick release fitting being located in the engine bay.

- A lower fire hazard risk. Air compressors become extremely hot while under load and the last thing you want is clothing, carpet, paper or any other flammable material being too close to it and catching fire.

- Smaller and less holes in the firewall. Instead of running a thick wire harness for the air compressor power harness and rocker switches you only need a small hole for the rocker switch harness.

- No unnecessary holes in the cab floor. If you use the air compressor with air lockers you will most likely have to drill holes somewhere in the floor for your air locker air lines to come in and connect to the air supply.

Manual & Guides

Our installation manual as well as community contributed installation videos can be found on our Manuals & Guides page.

Frequently Asked Questions (FAQ)

What if I have ARB Air Lockers and need the ARB Air Locker Manifold (ARB 171503)?

If your setup requires an ARB air locker manifold we have good news for you, this bracket supports mounting the ARB manifold out of the box. The ARB air locker manifold mounts to the underside of this bracket closest to the vehicle firewall. Giving you enough room to access your quick release coupling for air tools and the front and rear air locker solenoids and their air lines for maintenance and serviceability.

Vehicle Year/Model that are compatible

- 2001-2002 4Runner

- 2001-2002 Tacoma

- 1996-2000 Toyota Tacoma without ABS is usually compatible.

- 1996-2000 Toyota 4Runner without ABS is usually compatible.

- 1996-2000 Tacoma may be supported, but fitment on many of these years have not yet been confirmed.

If you don’t see your vehicle above, please contact us with your Year/Model/Trim to verify fitment. NOTE: If you don’t see your Year/Model in the compatible list IT DOES NOT MEAN YOU’RE VEHICLE IS NOT COMPATIBLE.

Vehicle Year/Models that are not compatible

- 1996-2000 Toyota 4Runner with passenger-side ABS pump.

- 1996-2000 Toyota Tacoma with passenger-side ABS pump.

What air compressors are compatible with this ARB air compressor bracket?

- ARB CKMTA12 / CKMTA24 – ARB High Output Air Compressor (Twin Motor)

- ARB CKMA12 / CKMA24 – ARB High Output Air Compressor (Single Motor)

- ARB CKSA12 – ARB Air Locker Activation

- Up Down Air EGOI 2 (Twin Motor)

Lifetime Limited Warranty

We’re confident in our build quality standards and that’s why we offer Lifetime Limited Warranty on this product when you buy it directly from us.

- Structural Guarantee: We guarantee the structural integrity of the bracket will last for years to come. If the bracket breaks or bends we’ll replace the bracket for FREE.

- Powder Coat/Finish Coat Guarantee: Powder coat is a hard one to Warranty because no powder coat is invincible to metal edges and even fastener threads. However, with that being said we’ll Warranty the powder coat under the following rules:

- Until you receive the item at your front doorstep: We’ll cover manufacturer defects, damages during shipping and overlooked imperfections during quality control.

- Every powder coated part will have “hang” marks left behind and there’s no way around this. However, our quality assurance and quality control processes take care of these hang marks and clean/seal/cover them appropriately. We can’t offer warranty against powder coat “hang” marks that have already been cleaned up by our quality control process. However if you believe you received a part that has “hang” marks that were missed during our quality control process please contact us.

- After you’ve handled the product: For up to 2 years we’ll guarantee against rust and corrosion forming underneath the undamaged powder coating. This may happen if the part was not properly sand blasted and cleaned prior to powder coating.

- Fastener & Hardware Guarantee: We guarantee our Black Oxide Stainless Steel fasteners. If they break we will replace them.

For Lifetime Limited Warranty claims please contact us and be prepared to provide your order details, photos of the damaged product and other information that we’ll need to verify your purchase and identity. This Warranty is only valid for the original owner and cannot be transferred to another person.

Made in the USA.

Additional information

Weight 6 lbs Dimensions 12.5 × 12.5 × 8 in Material Mild Steel

Powder Coating Textured Black

Air Compressor ARB CKMA12, ARB CKMA24, ARB CKMTA12, ARB CKMTA24, ARB CKSA12, Other, Up Down Air – EGOI 2

Vehicle Make Toyota

Vehicle Model 4Runner, Tacoma

Vehicle Year 1995, 1996, 1997, 1998, 1999, 2000, 2001, 2002, 2003, 2004

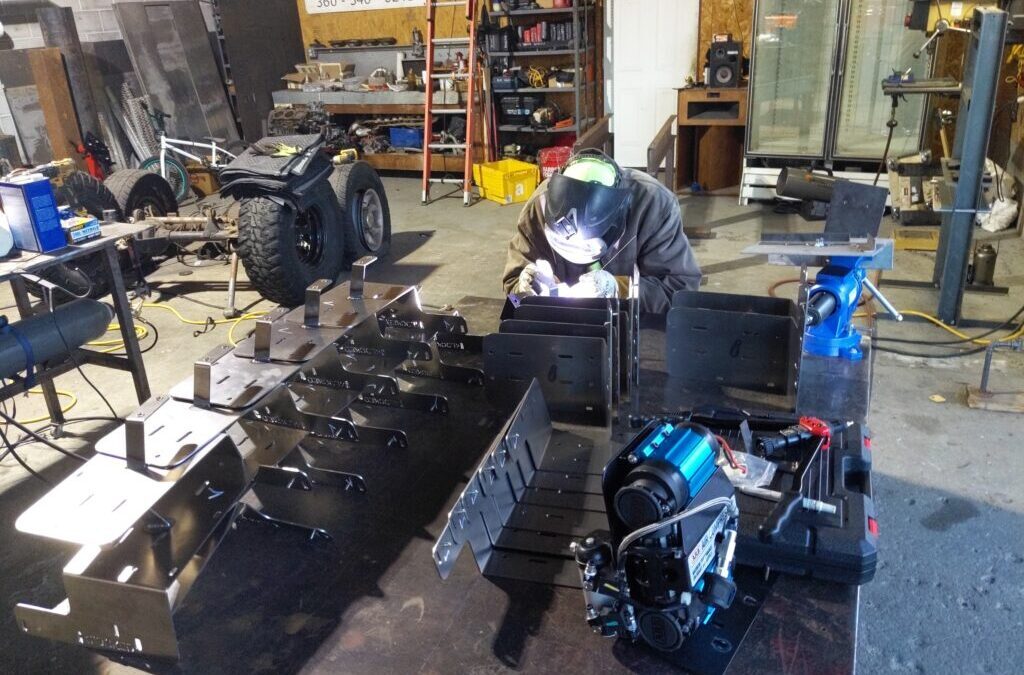

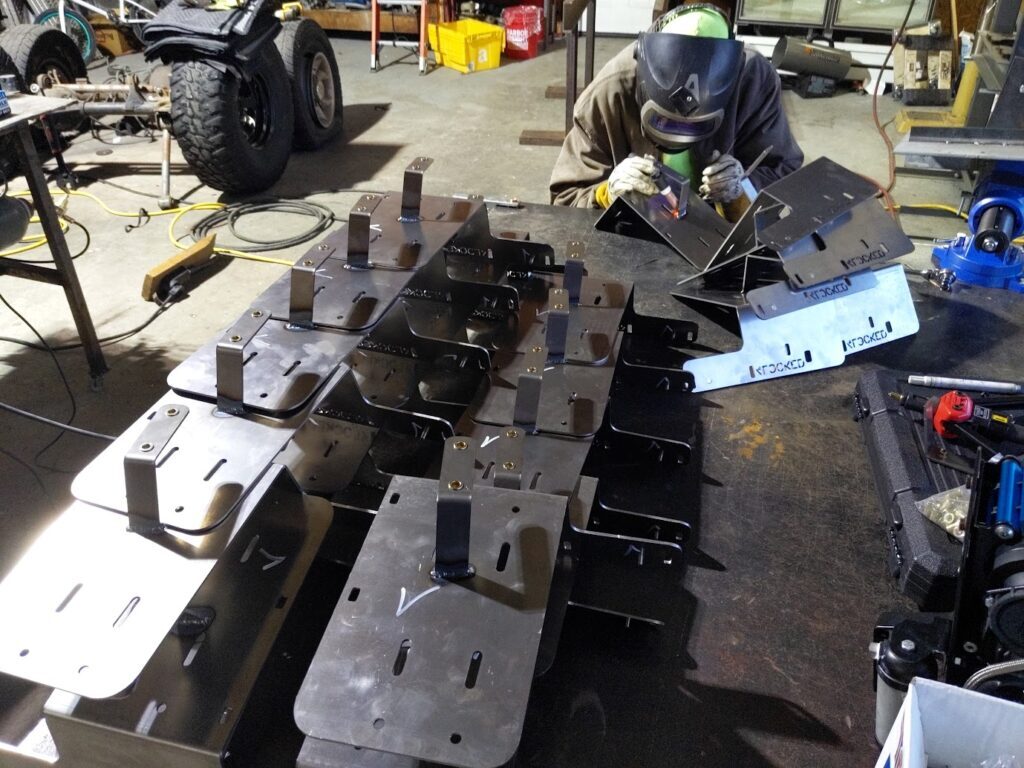

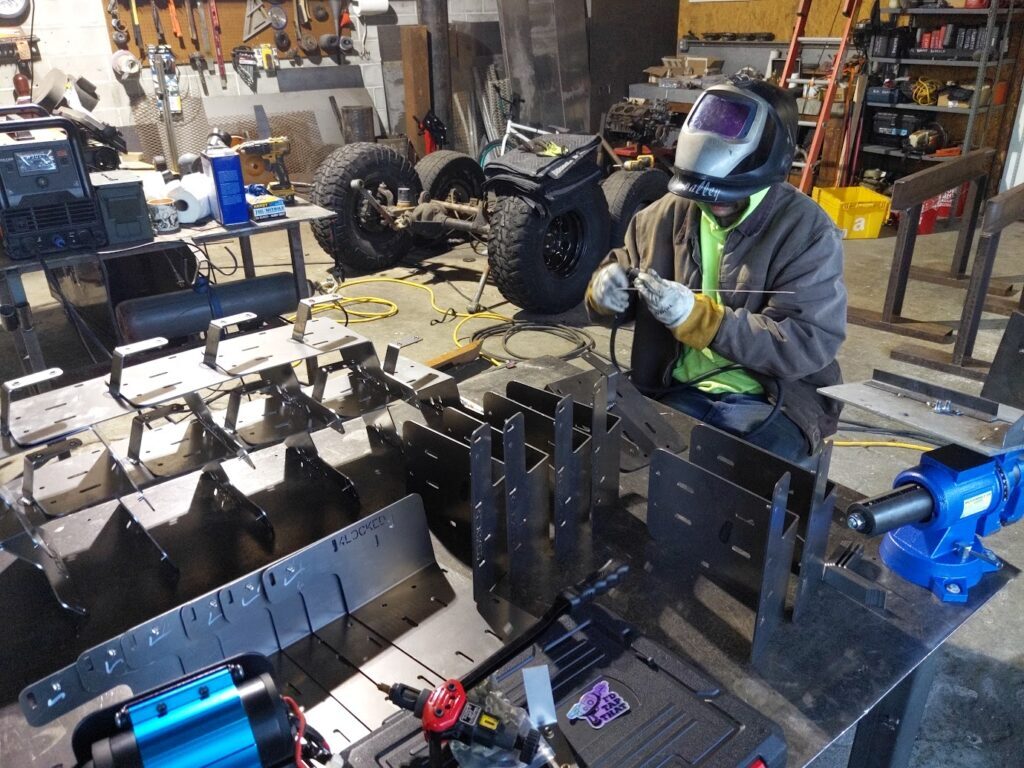

Above. Our outsourced welder, Warren House, owner of Sky Valley Welding. He’s Tig welding the first batch of 25 ARB air compressor brackets on January 27th 2023. Notice how each bracket has white paint-pen check marks on them. Those are indicating the areas (usually fasteners & welds) that passed our Quality Inspection process.

Warren opted to TIG weld the ARB brackets instead of MIG weld them. MIG welding them would’ve been far quicker and he’d probably be done with them in about an hour or two tops. However, he understands the strength and quality these brackets demand and the unknown environment they’re in. Since they have to hold upwards of 20lb of dead air compressor weight in a vehicle engine bay (that may be used for jumping desert dunes or forest roads) — he went with TIG welding to ensure the strongest possible welds.

It seems he can do just about anything when it comes to welding. If you’re ever in need of a quality welder regardless if its a vehicle, residential or commercial project you should reach out to Warren House. Just like us, you will be impressed and happy with the results.